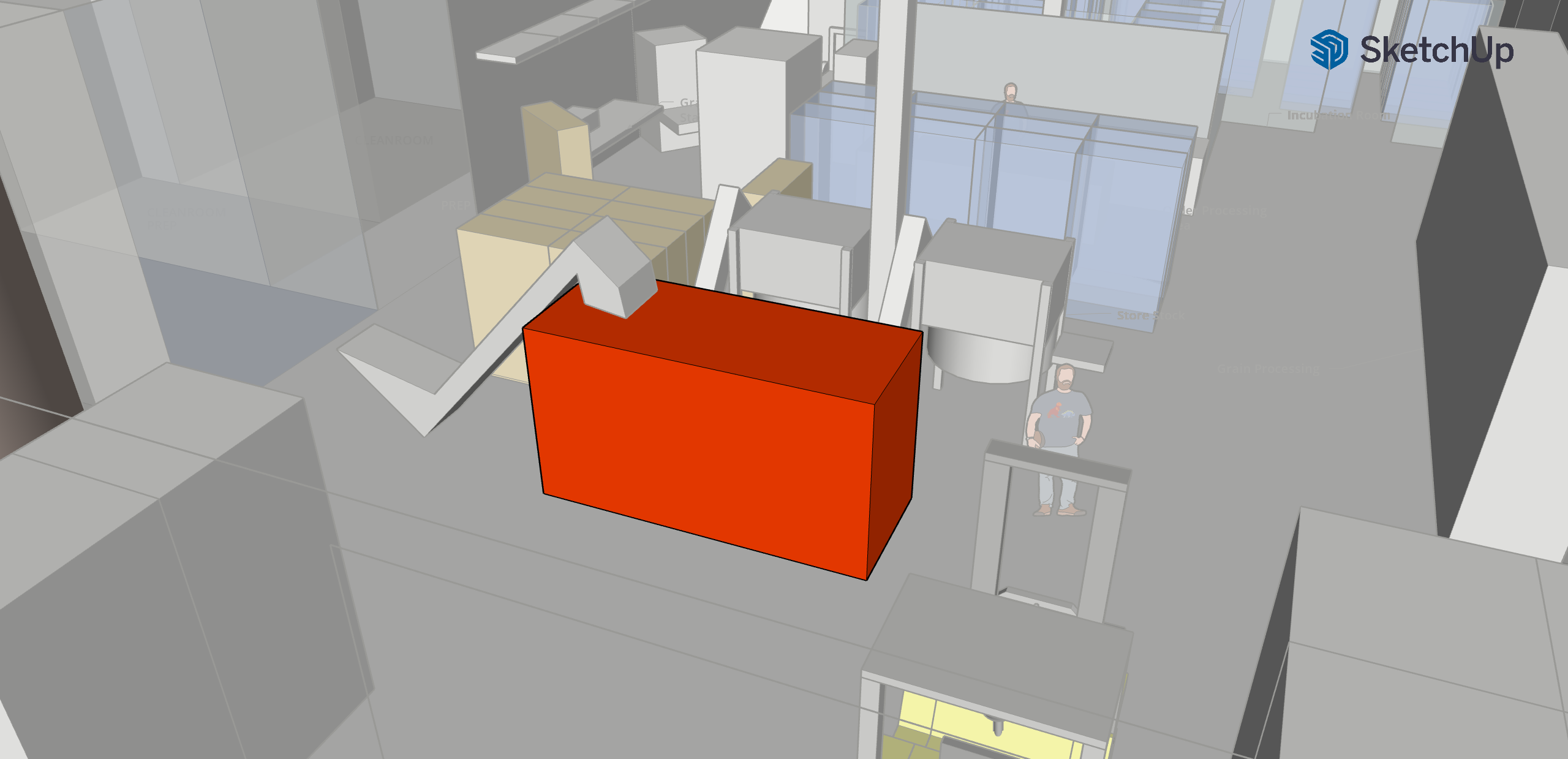

Precision Hydration & High-Capacity Mixing

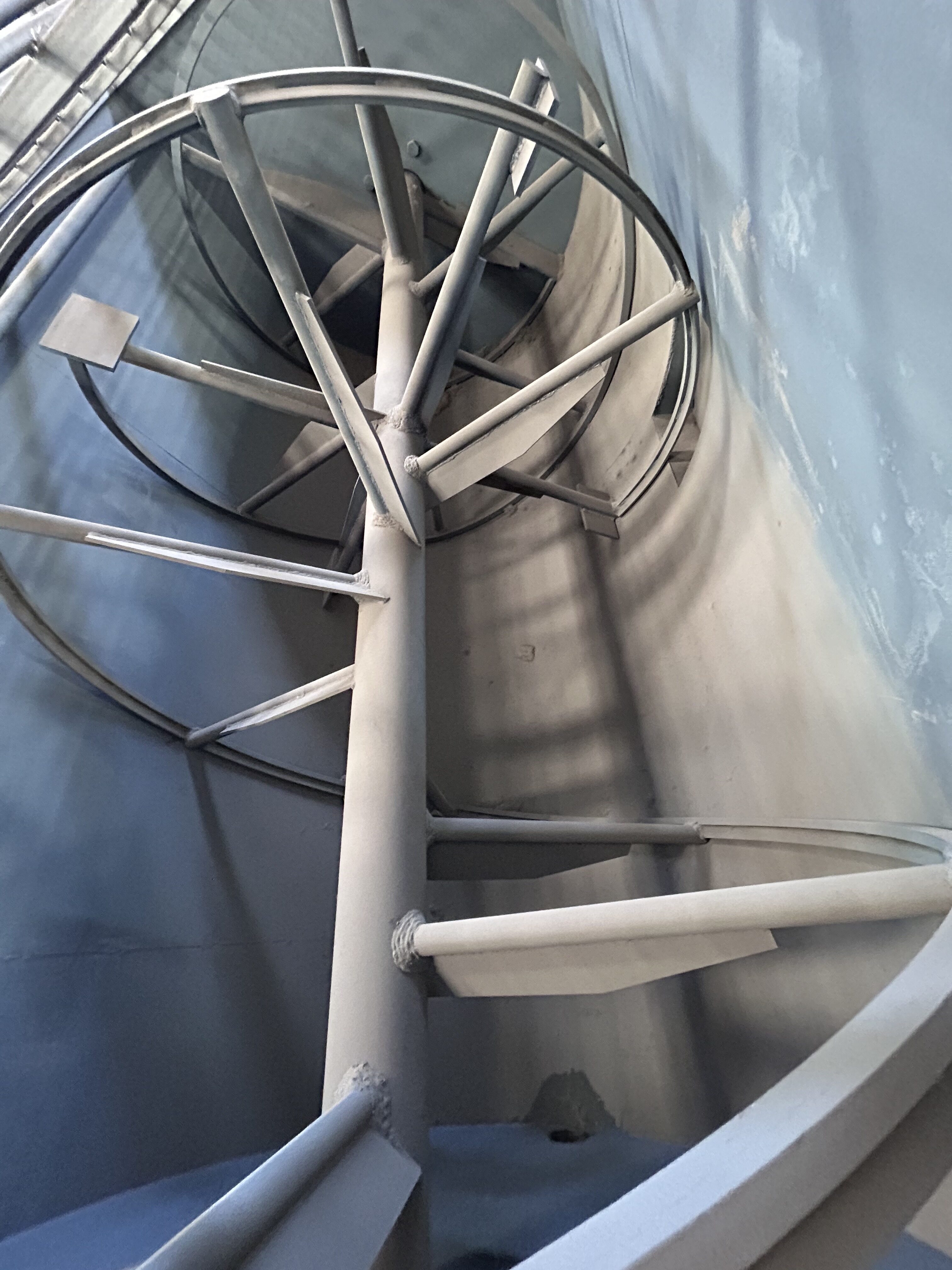

A 4 cubic metre ribbon substrate mixer is an essential part of our automated substrate production line, allowing us to efficiently mix and hydrate raw materials before bagging. Supplied by a leading dedicated supplier of commercial mushroom processing equipment, this mixer has a 2-tonne wet substrate capacity per batch, ensuring consistent hydration, uniform texture, and high efficiency.

With built-in water distribution, a high-torque geared motor, and a pneumatic-controlled dispensing gate, this mixer eliminates manual labour and ensures perfectly hydrated substrate for every batch.

Why This Machine is Essential

Large Capacity & Efficiency – Mixes 2 tonnes of wet substrate per batch, allowing us to process one full autoclave load per cycle.

Automated Hydration – Built-in water pipe system ensures precise hydration levels for optimal mycelium growth.

Seamless Workflow Integration – The mixed substrate is automatically dispensed onto elevators, feeding directly into the bagging machines.

High-Torque Motor for Effective Mixing – A geared motor with high torque ensures all raw materials are evenly broken down, preventing dry spots and inconsistencies.

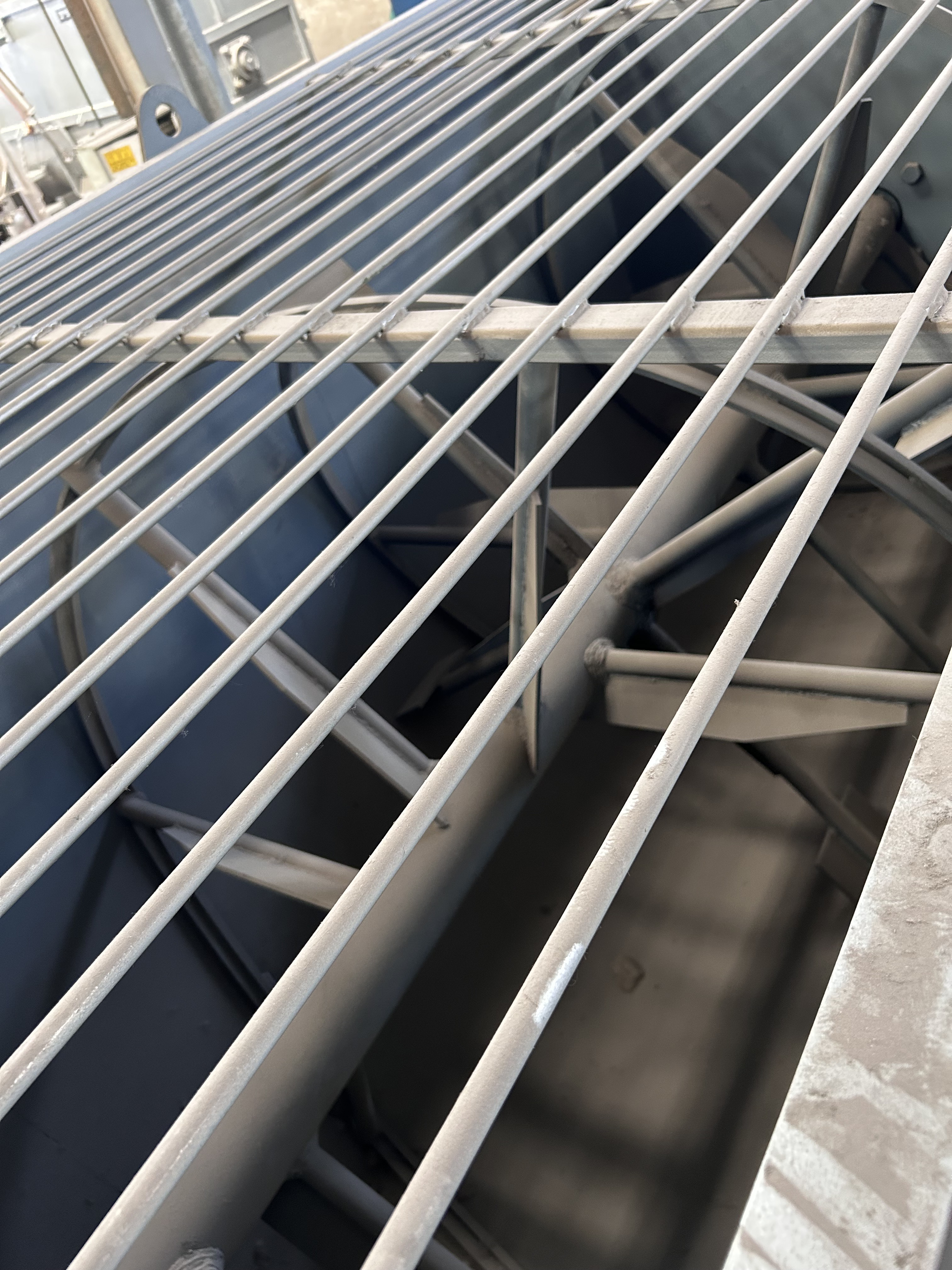

Safe & Low-Maintenance Design – Safety grate protects operators, while the simple, robust construction minimises maintenance requirements.

The Role of the Substrate Mixer in Our Facility

Hydrates & Mixes Raw Materials – Ensures substrate reaches the correct moisture content before bagging.

Feeds Directly into the Automated Line – Mixed substrate is dispensed via a computer-controlled pneumatic gate onto elevators leading to the bagging machines.

Eliminates the Need for Multiple Mixers – The large capacity removes batch-splitting, streamlining production.

Easy to Clean & Maintain – Spacious interior allows for quick and safe cleaning, reducing downtime.

Additional Info

Payment Terms: 50% upfront, 50% upon loading

Lead time / Production Time: 3 months

Shipping Time: Sea Cargo, 50 days.

Why We Need Funding for This Equipment

This high-capacity mixer is essential for ensuring consistency, efficiency, and automation in our substrate production. By investing in this machine, we eliminate manual mixing, reduce labour, and optimise substrate quality, ensuring a steady, high-quality supply for growers.