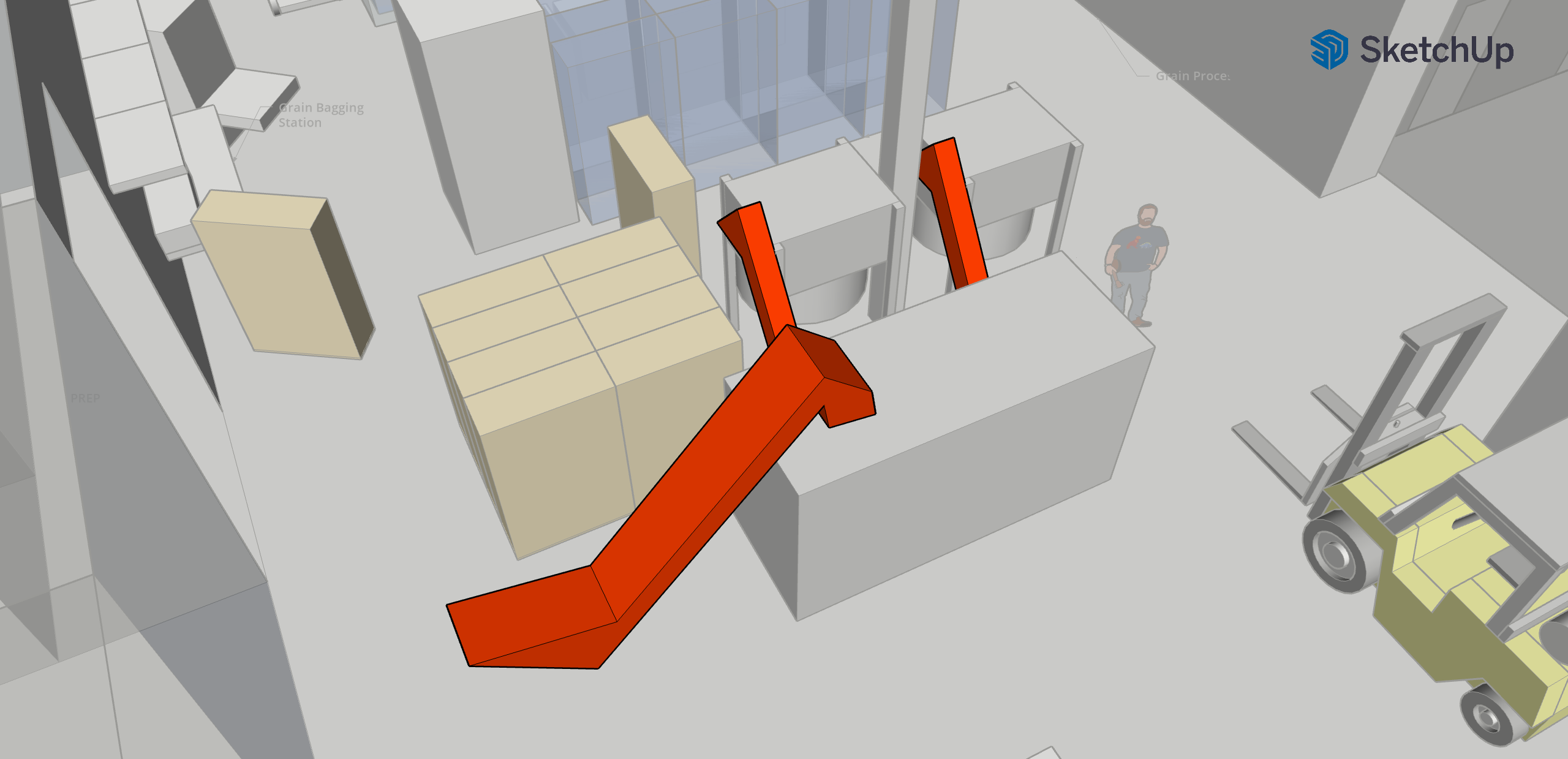

Automating Material Transport for Efficiency & Precision

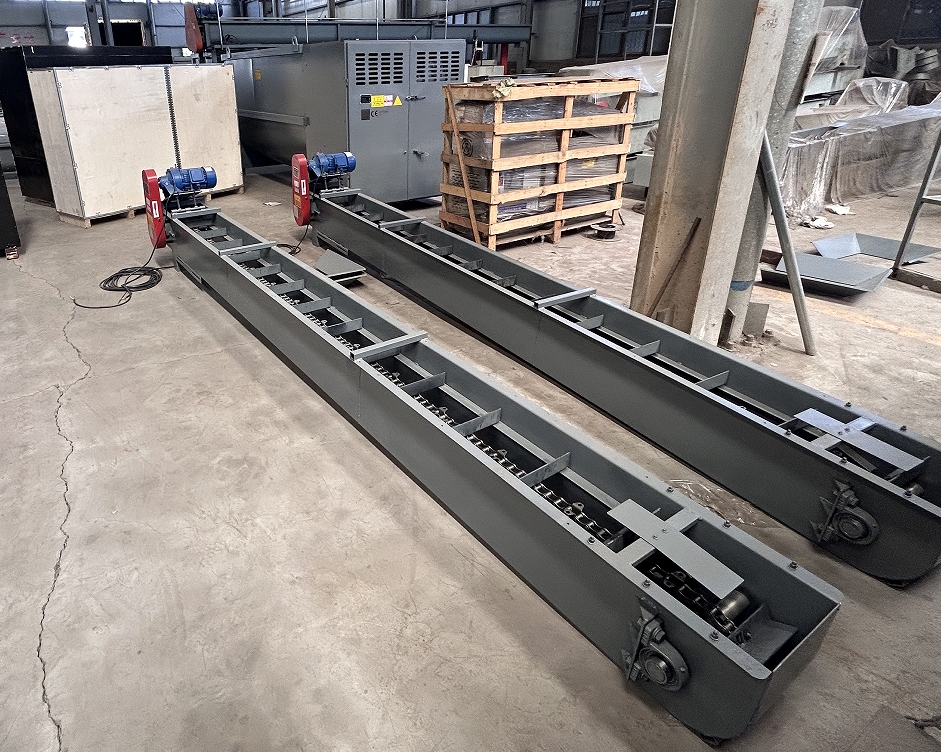

Substrate elevators are a key part of our automated production system, eliminating the need for manual lifting and transport of heavy materials. These speed-controlled conveyors streamline the movement of raw and hydrated substrate between machines, keeping production efficient, consistent, and contamination-free.

We require three substrate elevators:

- One large 4m elevator to transport dry raw materials into the ribbon mixer for hydration and mixing.

- Two smaller elevators to transfer hydrated substrate from the ribbon mixer to the automated bagging machines.

These low-maintenance, simple-to-operate machines reduce labour, prevent unnecessary handling, and ensure a smooth, automated workflow.

Why These Machines are Essential

Eliminates Heavy Lifting – Moves large volumes of substrate automatically, reducing labour demands.

Optimises Workflow – Ensures a steady, controlled feed of raw and mixed materials, keeping production running efficiently.

Speed-Controlled for Precision – Adjustable speed allows for seamless integration into our production process.

Reduces Waste & Contamination – Direct transport from machine to machine minimises spills and contamination risks.

Low Maintenance & Simple Operation – Few moving parts make these elevators reliable, durable, and easy to maintain.

The Role of the Substrate Elevators in Our Facility

The 4m Elevator – Moves dry raw materials into the ribbon mixer for hydration and blending.

Two Smaller Elevators – Transfer hydrated substrate from the mixer to the bagging machines, ensuring a steady, uniform feed.

Supports a Fully Automated System – Keeps machines stationary, preventing unnecessary handling and improving hygiene.

Additional Info

Payment Terms: 50% upfront, 50% upon loading

Lead time / Production Time: 1 months

Shipping Time: Sea Cargo, 50 days.

Why We Need Funding for This Equipment

These elevators remove one of the most time-consuming and labour-intensive tasks in mushroom cultivation – transporting heavy materials between machines. By investing in this system, we increase efficiency, reduce strain on workers, and maintain a cleaner, more sterile production environment.