Precision Inoculation for Sterile, High-Volume Production

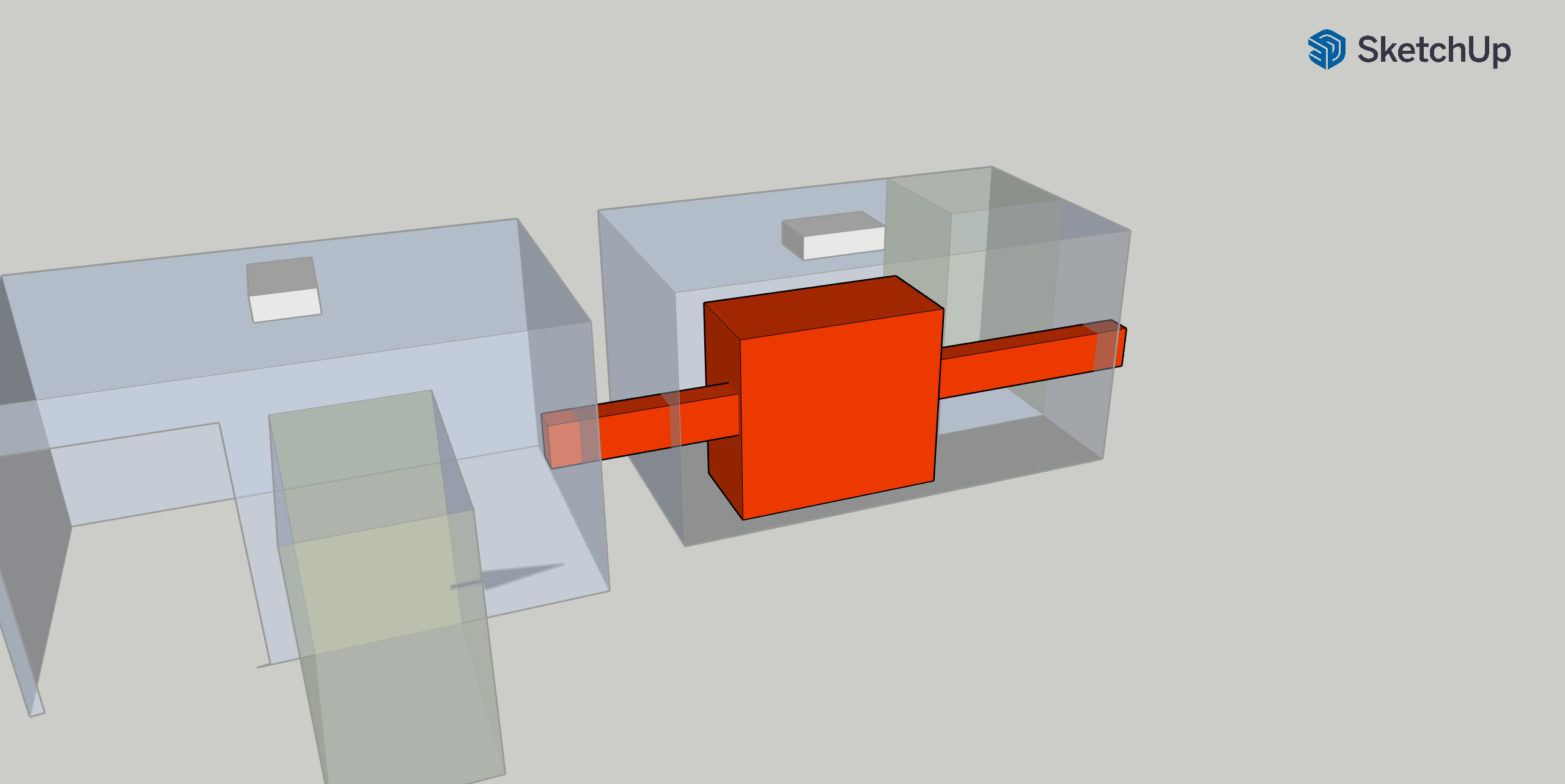

A high-precision, fully automated bag inoculation machine is essential for ensuring contamination-free, large-scale mushroom substrate production. Designed and manufactured by a global leader in mushroom cultivation technology, this machine enables fast, consistent, and sterile inoculation of substrate blocks, eliminating human error and reducing contamination risks.

With the capability to seal 500 blocks per hour, this machine is a key component in our sterile workflow, allowing us to scale production efficiently while maintaining the highest industry standards.

Why This Automated Inoculation Machine is Essential

High-Speed & Precision Inoculation – Automatically opens, inoculates, and seals bags at a rate of 500 blocks per hour, ensuring fast, contamination-free processing.

Fully Integrated with Our Cleanroom System – Located inside an ISO-rated cleanroom, maintaining strict sterility standards.

Hands-Free, Conveyor Belt Operation – Blocks move through the system without an operator, reducing contamination risks and labour costs.

Eliminates Human Error – Precise automated dispensing of mushroom grain spawn ensures consistent colonisation and batch quality.

Seamless Workflow – Once inoculated, blocks pass through a hatch into a temperature-controlled incubation environment, where mycelium fully colonises the substrate before shipping to customers.

The Role of The Inoculation Machine in Our Facility

Reduces Manual Labour – Eliminates the need for manual bag handling, increasing efficiency and reliability.

Ensures Sterility – Housed in a HEPA-filtered cleanroom, protecting inoculated blocks from airborne contaminants.

Supports Large-Scale Production – Enables a fully automated, high-capacity workflow, critical for meeting industry demand.

Optimises Growth Success – Ensures uniform spawn distribution for faster, more consistent mycelium colonisation.

Additional Info

Payment Terms: 50% upfront, 50% upon loading

Lead time / Production Time: 4 months

Shipping Time: Sea Cargo, 50 days.

Why We Need Funding for This Equipment

This automated inoculation machine is critical to achieving a fully sterile, high-volume production process. By removing manual handling and human error, it ensures a clean, efficient, and scalable solution for UK mushroom cultivation.